Small changes add up to a big impact. The idea that led to the fuel efficiency initiative is poised to save between 75 to 80 litres of fuel per day, reducing costs and emissions at Ekati mine and improving overall environmental performance. Overseeing these operational changes is Mike Sluggett, Senior Manager, Fixed Asset Maintenance. Mike keeps a keen eye on every potential excess energy use and machinery idle time to best manage fuel optimization and energy consumption. He also supervises the maintenance of the processing plant and all other fixed assets, including the powerhouse and all outbuildings on the property.

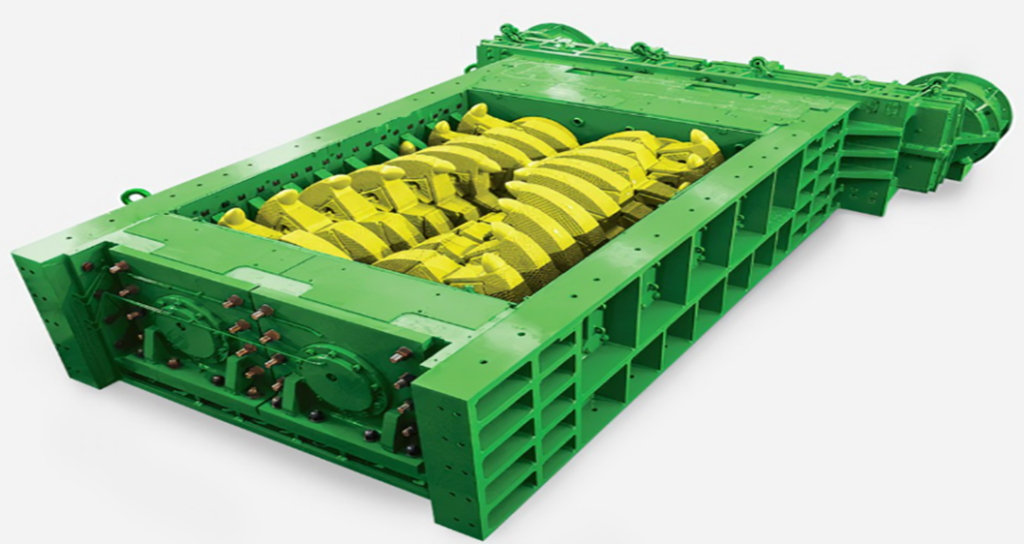

While contemplating ways to run the processing plant more efficiently, Process Operations & Fixed Maintenance, with the help of Superintendent Process Plant Ryan Rickson, the team has been experimenting with reducing the sizers’ operational time by utilizing batch processing. Sizers are large machines used in the processing plant to breakdown hard rock minerals and separate kimberlite. By eliminating the requirement for continuously processing kimberlite through all three sizers, they can take a fourth generator offline and still achieve processing targets.

This idea was put forward for approval through Burgundy’s Business Improvement initiative, which was launched in September 2023 and focuses on cost reduction across the company through grassroots employee ideas being put forward for consideration and approval with senior leadership. Leaning on the success of the large-scale initiative and the positive results of this idea, Mike is motivated to inspire further improvements.

Sharing this success story has encouraged people at Ekati to implement a zero idling policy and safely shut down vehicles and other fuel consumers when not in use. Mike also spends time educating coworkers to consider more personal energy efficient tactics, such as turning down room temperatures daily when on shift or away from their accommodations. While small, these behaviours can result in a large cumulative impact on cost savings and fuel reduction.

Energy for You Project

In an associated fuel savings opportunity, the Energy for You (EFOY) project reduced fuel consumption at eight radio communication towers located along the Misery haul road. This involves using a 7.2 kW solar panel system to power remote communication towers that previously used diesel fuel. The project reduced greenhouse gas emissions by five per cent, eliminated diesel fuel use for the radio communication towers and reduced overall diesel fuel usage at Ekati mine by 11,307 litres per year.

These operational improvements prove that reducing fuel consumption has positive impacts on both financial and environmental outcomes. However, their long-term success is dependent on people. Forming new, positive habits is generally not an easy task, but ultimately, it is important to remember that every change, even small changes, can lead to big outcomes.